Yokohama Fender

TYPE I (Net Type) 1. Rubber Sleeve | TYPE II ( Sling Type ) 2. Aircraft Tire Net |

3. Double Cover (DC)

Double cover consists of a single cover with an extra tyre cord layer and outer rubber. It is better resistance to operational damage such as abrasion, cuts and gauges. Yokohama fender Double Cover

Yokohama fender Double Cover

4. Low-Pressure (LP) Yokohama Fender Low Pressure

Yokohama Fender Low Pressure

Low-Pressure fenders are designed with a lighter body construction. It is popular for application requiring large clearance between ship and jetty or between two ships but not necessarily needing the high performance of a standard pressure fender.

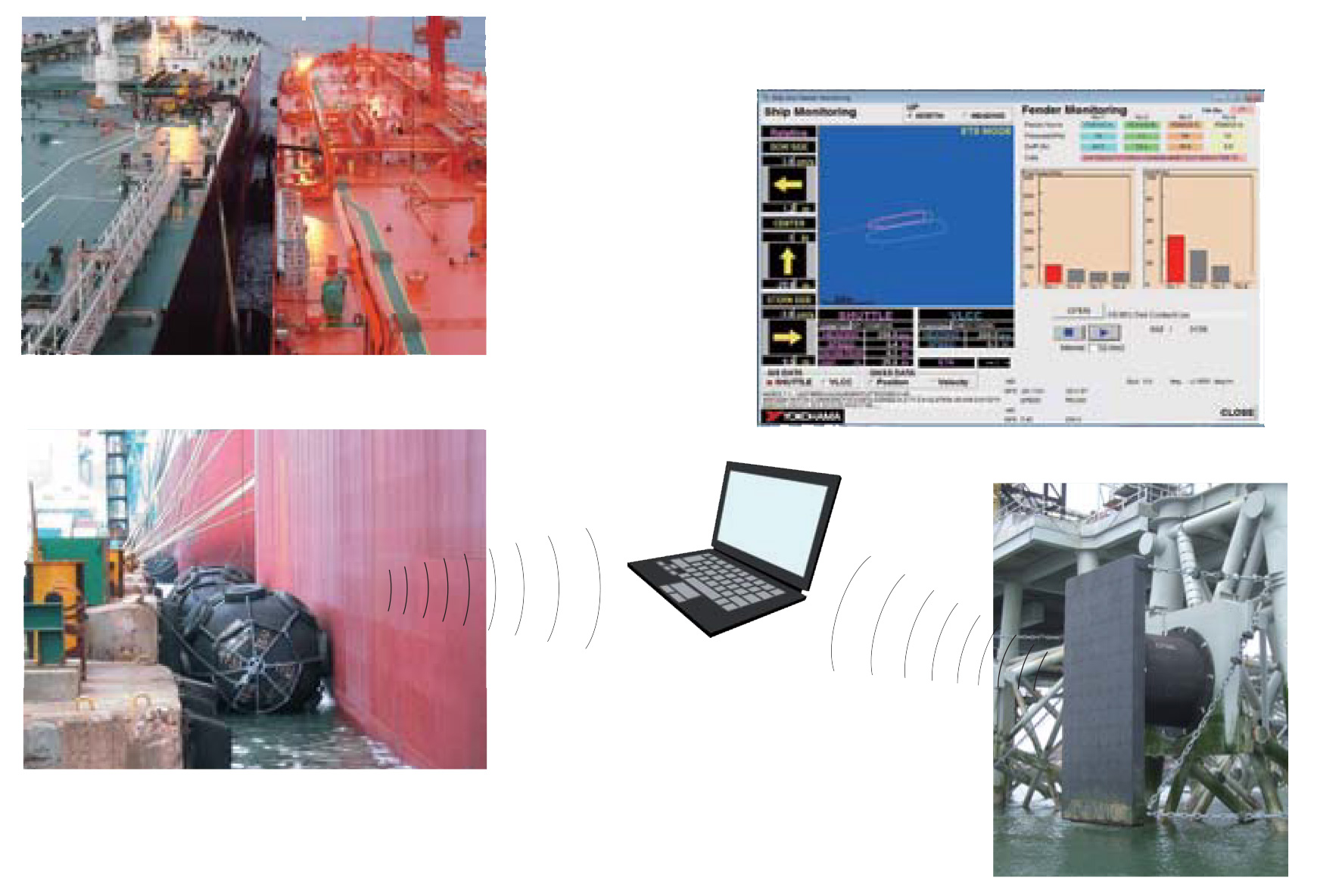

5. Fender Monitoring System (FMS)

Fender Monitoring System has been developed to monitor offshore Ship-To-Ship (STS) operation. The system incorporates technology from the design of pneumatic fenders and the numerical simulation analysis of dynamic ship motion.

The system can simultaneously monitor the state of pneumatic fenders used as shock absorber between the two ships and the behavior of both ships. This wireless fender-monitoring system can be also applied to onshore Ship-to-Dock operation anywhere in the world.

Yokohama Fender Monitoring System

Yokohama Fender Monitoring System

6. Globuoy Yokohama Fender Globuoy

Yokohama Fender Globuoy

Globuoy is a modified pneumatic fender and used as a surface or sub-sea buoy for equipment installation, mooring, anchoring and various offshore operations. It can be also used with higher working pressure or can be filled with pressure resistant material for various under water applications. It is a non-collapsible buoy in case of over-submergence.

7. Vertical Yokohama Fender Vertical

Yokohama Fender Vertical

Vertical-Pneumatic fenders are specially designed to be installed vertically (Hydro-pneumatic fenders are water-ballasted). They are popular with vessels whose berthing point is below the water line such as catamaran ships, semi-submersibles platforms or other submersibles. Also, they are suitable as secondary fenders at both bow and stern of ship.

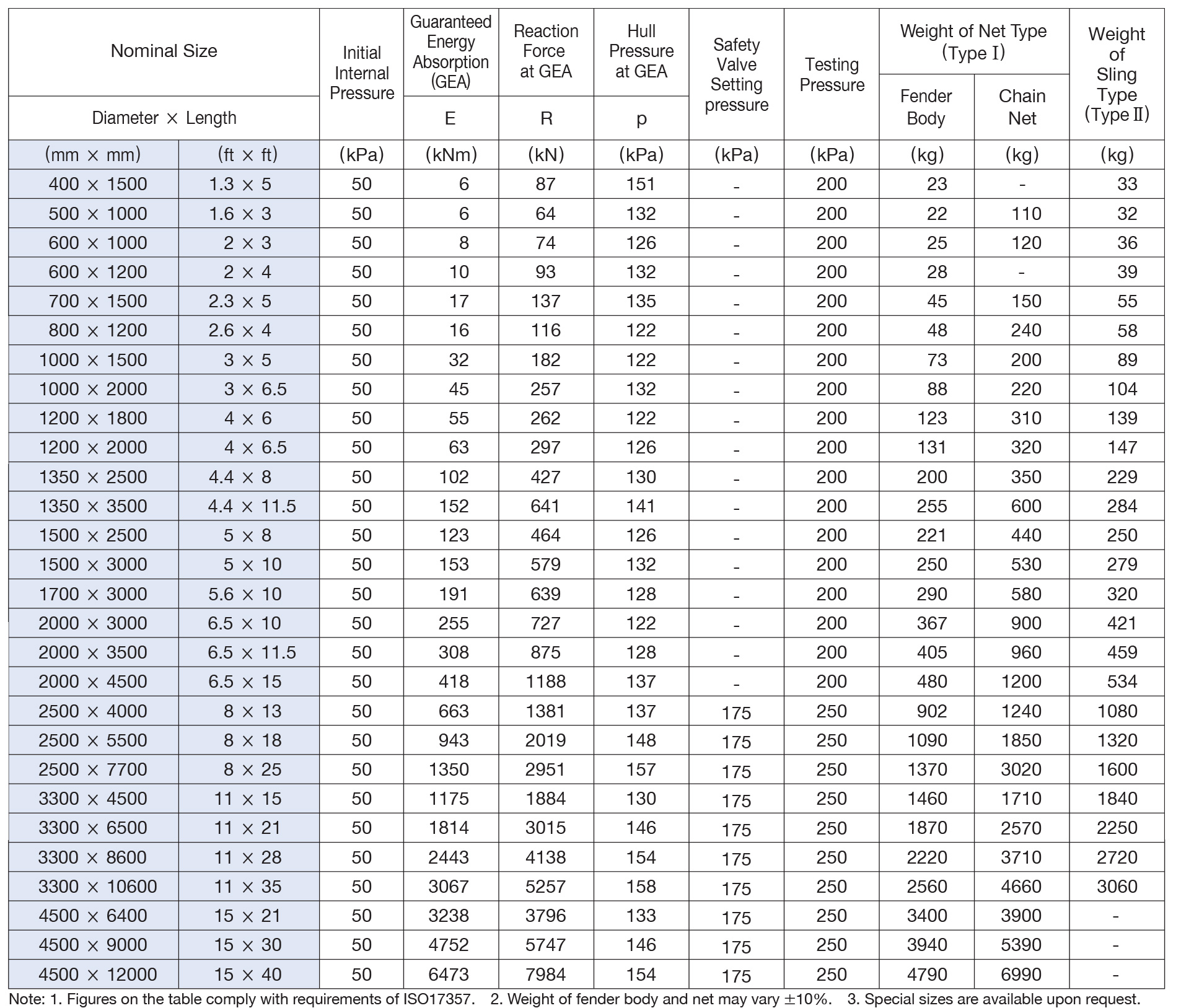

YOKOHAMA FENDERS SIZE AND PERFORMANCE TABLE

Pneumatic Floating Fender

Yokohama Fenders Sizes and Perfomances

Yokohama Fenders Sizes and Perfomances

ADVANTAGES

THE YOKOHAMA RUBBER CO., LTD. confirms that all its Pneumatic Rubber Fenders fully

comply with all requirements of ISO17357 and PIANC : 2002 “Guidelines for the design

of fender systems,” Appendix “B”.

1. Safety and Reliability

YOKOHAMA Fenders are constructed of several layers of strong tire-cord, and are thus resistant to pressure and cutting.

2. No Deterioration or Variation in Performance

YOKOHAMA Fenders utilize the compressive elasticity of air, therefore performance deterioration that you generally see in Solid Cell and Foam Fenders due to fatigue is absent.

3. Advantages at Inclined Berthing

Energy absorption of YOKOHAMA Fenders does not decrease at inclined compression up to 15 degress. However, it is necessary to use larger sizes in the case of Solid Cell and Foam Fenders in order to compensate for the decrease of energy absorption at

inclined compression.

4. Soft Reaction Force

Reaction force of YOKOHAMA Fenders does not increase sharply even under excess load conditions. They work so well to

restrain the sway and have enough energy absorption considering dynamic mooring conditions.

5. Lower Mooring Forces under Rough Conditions

Reaction force and deflection of Solid Cell Fenders easily reach their respective maximums that might cause the damage to ship's hulls. On the other hand, the reaction force of YOKOHAMA Fenders increases slowly and the allowable deflection is wide.

They safely protects ships and mooring facilities even under rough weather conditions.

6. Strong against Shearing Force

YOKOHAMA Fenders are adequately reinforced by means of strong tire-cord against shearing and compression forces.

Such forces present a dangerous threats to Solid Cell Fenders because they are not well reinforced.

7. Shipping Cost Minimization

Pneumatic Floating Fenders are usually packed and shipped in containers or on pallets in vacuumed and folded down state. However, there are huge shipping costs when Foam Fenders are delivered because they can not be deflated.